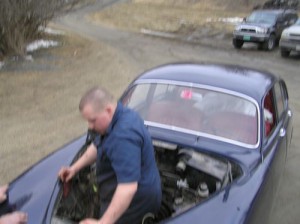

March has arrived, and with it, a foot of snow on the very first day. Although it’s a taddy-bit late to save the ski season, the change from a dull brown landscape is quite arresting, and here, once again is proof that you can “Do It In An MGB’.

This is, of course, my faithful blue winter beater #2 (see January, 2011 posts for more particulars). Suffice it to say that with four studded snow tires, as can be seen here, it’s a formidable winter conveyance.

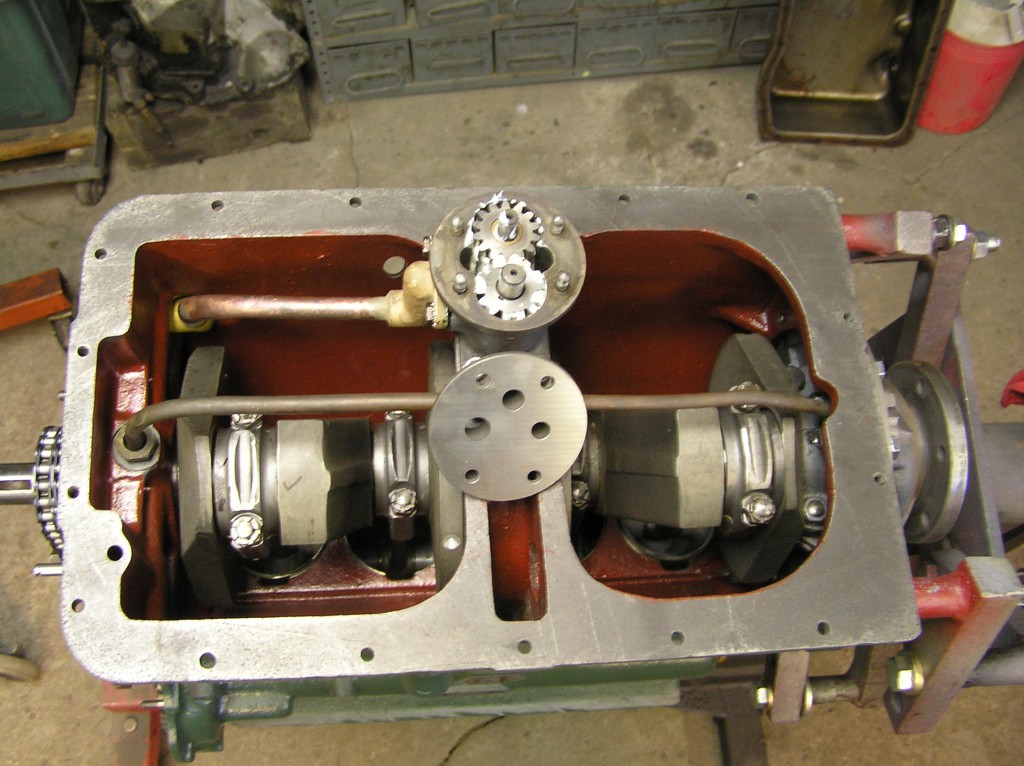

Here’s a view from the other side of the blue worktable. Patrick is using our 360 degree transmission stand to assemble this MG TD gearbox. It makes assembly work a little easier if you don’t have the chase the TX across your workbench.

Behind his left shoulder is our ex-War Department Reid surface grinder, and in front of his right hand is Churchill Special Tool 18G 42A, a main bearing cap puller for “B” & “C” series engines, and for which we’ve also fabricated adaptors for use on TR3 main caps, as well. Above that is our electric engraver, with which we scratch the cam grind number and clearance info. inside the valve covers of every engine we overhaul, and where we hope subsequent owners and repairers will find it.

The white plastic tool with the white steel handle aligns the rear oil slinger on those TR3’s.

Late this afternoon Butch started bolting up the Australian DMD intake manifold to the BJ8. This car is quite near to running. We are told that this horizontal manifold is good for another 12 to 15 horsepower.

We hope so, because clearance for the fastening hardware is so severely restricted by the intake runners that we are using grade 5 jam nuts on the bridge washers because a standard hex nut won’t fit.