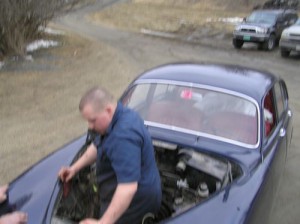

The owner of this freshly painted Jaguar Mk2 Sedan asked us to detail the engine bay. Although there would have been certain efficencies to doing it at the same time the car was painted, we’ve actually done most of our engine detail work separate and apart from a general refinishing.

This Jaguar has the Detroit Gear (Borg Warner) automatic once used by both Ford & Studebaker, and as had been mentioned on this page before, it is fairly unique in that it has an additional rear pump which can lock up the transmission and turn the engine on a rolling start. John just gotten done checking to make sure the torque converter was going to stay put on the trip back to the barn.

We’re in the beginning steps of putting together a high output engine for an MGB. The .100″ oversize pistons, made to our pattern by JE Pistons came in Tuesday.

These magnificent pistons are infinitely stronger forged (not cast) pistons which are dished for a nominal 8.7:1 compression ratio so the engine will run happily on readily available premium fuel.

The actual compression ratio will come in around 10:1 (still good with pump fuel) because the cylinder head is being pocket ported & cc’d by APT in Riverside California, and we’ll also be running an APT VP 11BK street cam.

The +.100″ overbore stays just within the fire ring around the cylinder bore of the head gasket. There are some big bore pistons on the market which don’t. That can be a problem with head gasket life, and it can also be a problem with cylinder block life when the water jackets around the cylinder bores get too thin.

It doesn’t have to be that way. We’re having the cylinder block sonic checked to determine cylinder wall thickness before any metal comes out. Every so often we end up preemptively sleeving a perilously thin cylinder. A little checking up front can save an awful lot of grief later.

Also pictured here is a storage solution that Mr Casey never came up with. We have a lot of work in the shop right now, and when Jason Marechaux at East Coast Collision & Restoration called up Monday and said ‘come & get it’ we did. This is a TD frame, or if you prefer, TF frame, the only difference being the chassis number. The working height is ideal for use as a chinning bar.

I took this picture a month ago, back when it used to still snow, a little. If you’re feeling a little nostalgic about the white stuff, well here it is. We’re not.