We’ve had an awful run of MG’s this winter, virtually all these posts have featured them. We have a few Jaguars up our sleeve, too, or perhaps more accurately, waiting in the barn, but we like MG’s and they are perhaps the “sine qua non” for understanding the zen aspects of british sports cars.

This particular MG, a TF 1500, last turned a wheel in 1965 or 1966 when a connecting rod started knocking, again, most likely as the result of a bodged earlier repair. In any event we were able to salvage the connecting rod, and Gary at Manchester Engine Rebuilders, working closely with his master crank-man Tony, was able to save the crank by welding the #3 con-rod journal with the end result being a .010″, .010″ crankshaft. Other than that, it’s the same old, same old careful fit up & assembly, running a +.040″ overbore and a slightly juiced cam.

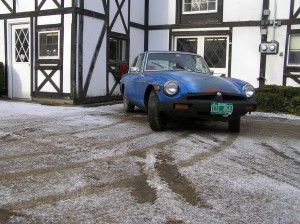

The owner of this car has been keeping faith with it since the ’50’s became the ’60’s.

Here’s a picture of the process of installing the camshaft in the optimum position for good running, which according to the cam grinder is 4 degrees advanced from a split overlap. Split overlap being the condition where the intake & exhaust opening & closing events are evenly distributed around top and bottom dead center. As a rough rule of thumb (sorry I know that’s not a P.C. expression), a camshaft installed advanced, i.e. with the intake open farther at TDC, will start to produce its power lower down the rpm range, just what you want on the street, really, whereas a cam installed retarded (with the exhaust open farther at TDC) shifts the peak power band farther up the rpm range, sometimes useful for racing.

We always paint all the major parts before we start assembly, and apply the final paint once the engine is completely assembled. In this picture you can see our MG TC paint mask valve cover and the thermostat housing turned backwards to get paint where it usually aint’. Not so obvious is the lockwire on the external camshaft staking bolts and the center hold down bolts on the oil pump.

Perhaps later we’ll be able to post up video shot with John’s iPhone of this car running around the yard under its own power for the first time in 45 years.