One of the basic diagnostic tests which is familiar to almost everyone is the cylinder compression test. Anytime compression pressures run within a range of 10% between the high & low cylinders everyone is happy. Sometimes, however, we’re looking for just a little more information from those same cylinders and in those circumstances we go with 2nd level diagnostics in the form of a leakdown test. This is also dead simple: Just add air and see how well the cylinder retains pressure. Above a 15% decay rate, everyone’s dancing in tall clover. This engine was in the zone.

While I was doing my engine diagnostics, Butch was preparing to recondition this BJ8 differential which ran a little too long with the drive flange loose. This didn’t do the pinion bearings any favors, and we decided that if we were going to have the whole thing apart for assessement and remediation, might as well replace all the bearings and reset it completely.

Once everything was cleaned up we found an exceptionally legible tolerance marking on the pinion gear: plus or minus zero. Because these typically ran as much as .005″ either way, this was definitely one of the Thursday gear sets. Fully assembled now,and painted black, it’s ready for reinstallation.

arrangement is lower A-arm & trunnion arangement which utilizes a threaded trunnion pin to locate the lower king pin in the A-arm. As long as it gets greased every thousand miles or so it works wonderfully well, and when it doesn’t get greased the male & female threads wear rapidly, producing an astonishing amount of transitional oversteer. At the very least, remediation means replacement of A-arm & trunnion pin, but most of the time it costs us a set of king pins, too, because the trunnion pins fuse themselves in place. The unique and almost obscenely expensive taper thrust wheel bearings can run the price up quite a bit.

By mid-week the action had shifted downstairs where John, operating the motor hoist, Butch steering the engine & suspension unit, and Steve controlling pitch & yaw with the floor jack, stuffed the driveline and suspension subframe unit back into this Mini Panel Van. It’s nice to step back sometimes from the two seat sports cars that are our principal interest and admire the handywork of one Alec Issigonis, who’s designs spanned the latter half of the 20th century and charged into the first few years of the 21st, first in the form of the Morris Minor, and after 1959 as the ubiquitous Austin Mini. So simple and yet so clever.

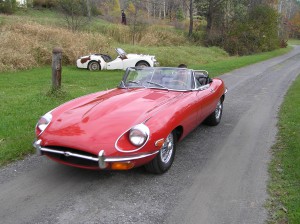

Here’s another reminder of sportscar 101: Road test your work, first before you start, then as you complete repair operations, and finally, when you think you’re done. We do this because it’s the first best way to quantify the results. We also do it because usually it’s really fun !