Sunbeam Alpines don’t show up here very often, so it’s always a special event when we have one in the shop. This particular Alpine was imported, I believe, from Alabama where it was subject to some creative repairing which we’ll get into in just a moment. But anyway, the good news is that it’s pretty solid underneath with new floors, even if the installing technician threw away the complete handbrake assembly when he was done.

Another interesting feature of this Alpine is the 2nd choke cable to the right of the steering column under the dashboard. The now ‘primary’ choke is under the ammeter, just right of the main lighting switch. Although the engine is correctly fitted with a pair of Stromberg 150 CD carburetors, they are the wrong 150 CD’s. They won’t take the factory air cleaners and their linkages, are also “creative”. Thus the two choke cables, one for each. More later as we go along.

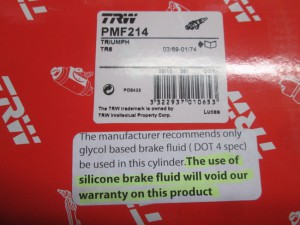

Silicon brake fluid is great stuff, if all you’re concerned about is keeping the paint from crazing on the bulkhead of your MGA 1600. Otherwise, it’s a source of grief for owners, and a continuing revenue stream for Sports Car Services. It leaks out. Some hydraulic seals don’t like it and rebel. It doesn’t trap moisture so that moisture can be removed by periodic flushing (every two years is our strong recommendation). The timely reminder on the left appears on the box containing a replacement TR6 brake master cylinder from TRW by way of our brake parts shelves. Heed the warning.

In other news, we have my XK 140 just about prepped for Wray Schelin at Pro Shaper Sheet Metal (see the web tile on the right). Because the vent door at the back of the fender went missing, another creative technician made the housing disappear. Did this guy work on Alpines too, I wonder ?

Back in the day, the front fenders were spot welded to the bulkhead and the joint was then lead loaded. Saturday was a nice, sunny day, so Patrick took his work outside and sweated out about 1/4 inch of lead filler, which was installed in 1955.

As it happens a very handy fix was available, another Hat Rabbit, if you will. This genuine Jaguar right front fender has been on hand for the last 40 years. Planning ahead as it were.

As a reminder, we don’t do paint & fender work, but sometimes we’ll do a little bit of prep. We retreated back indoors for this last photo. Here’s hoping winter will relax its icy grip from around our collective throats soon.